Democratizing Predictive Maintenance: Can Generative AI Close the Gap?

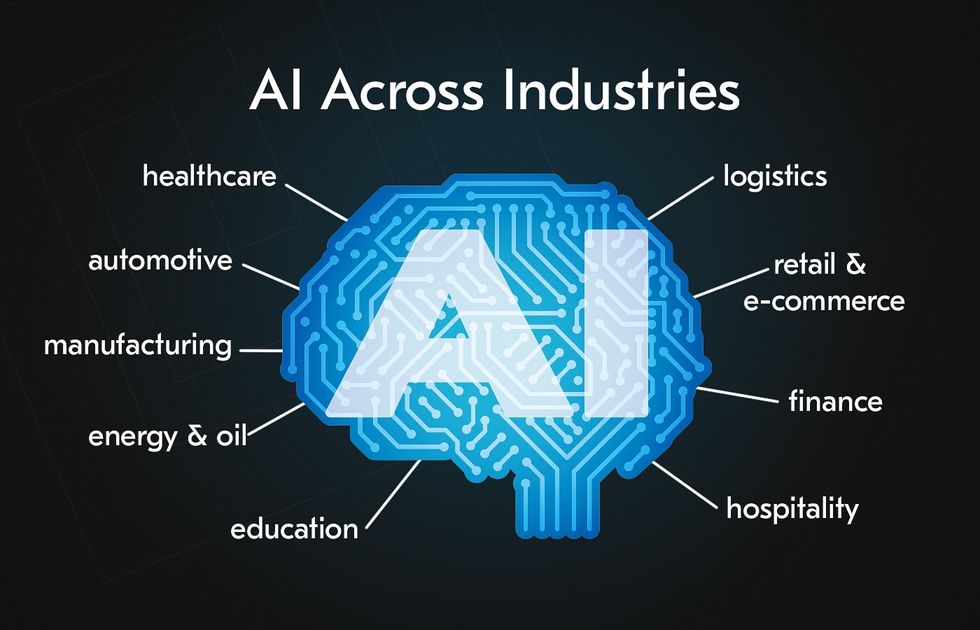

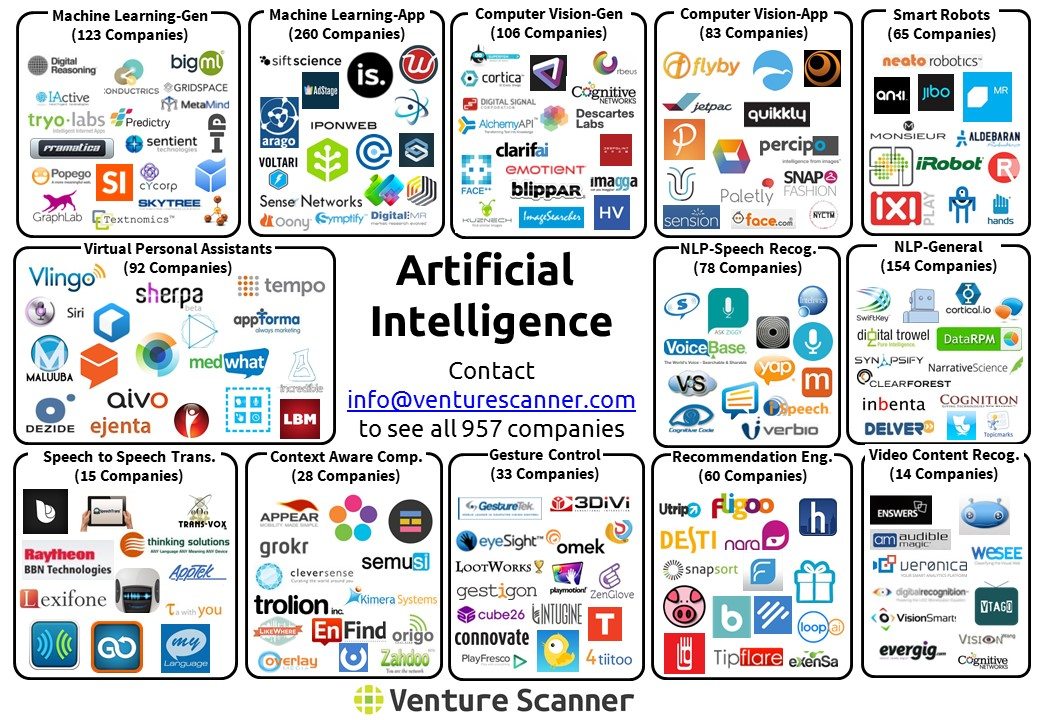

Industrial AI has been making waves in various areas, including asset management. Artificial intelligence (AI) is at the forefront of these digital technologies. As a journalist, I’ve had the opportunity to delve into the world of AI and its applications in the industrial sector.

AI for Asset Performance Management

AI is not new to the industrial world. In simple terms, AI refers to computer systems and programs that can simulate human intelligence, learn patterns, solve problems, and make decisions. Machine learning (ML), a subfield of AI, has found numerous use cases in the industrial world. ML focuses on algorithms that can learn from a wide range of data to make predictions and aid in decision-making.

AI is revolutionizing the industrial sector

AI is revolutionizing the industrial sector

Predictive maintenance (PdM) is an essential application of AI in the industrial world. PdM employs advanced modeling and ML technologies to analyze hundreds of process parameters over time, comparing them to historical asset data. This helps manufacturers estimate wear and degradation of assets or their parts and forecast asset failure in advance.

“Predictive maintenance technology has been around for a while, but its adoption rate is still low. Data gaps and scalability challenges are among the leading obstacles preventing wide-scale adoption.” - Yours truly

The Challenges of Predictive Maintenance

While manufacturers understand the benefits of PdM, not all manufacturers are able to reap its benefits. Successful implementation of PdM programs remains a major challenge. For a successful PdM program, it is imperative that the ML algorithms are trained on clean data, the right amount of data, and the right type of data.

Data gaps and poor system integrations lead to unreliable models

Another challenge associated with PdM has been scaling. Many organizations have been able to achieve success with their PdM program but only up until the pilot phase.

Generative AI to the Rescue

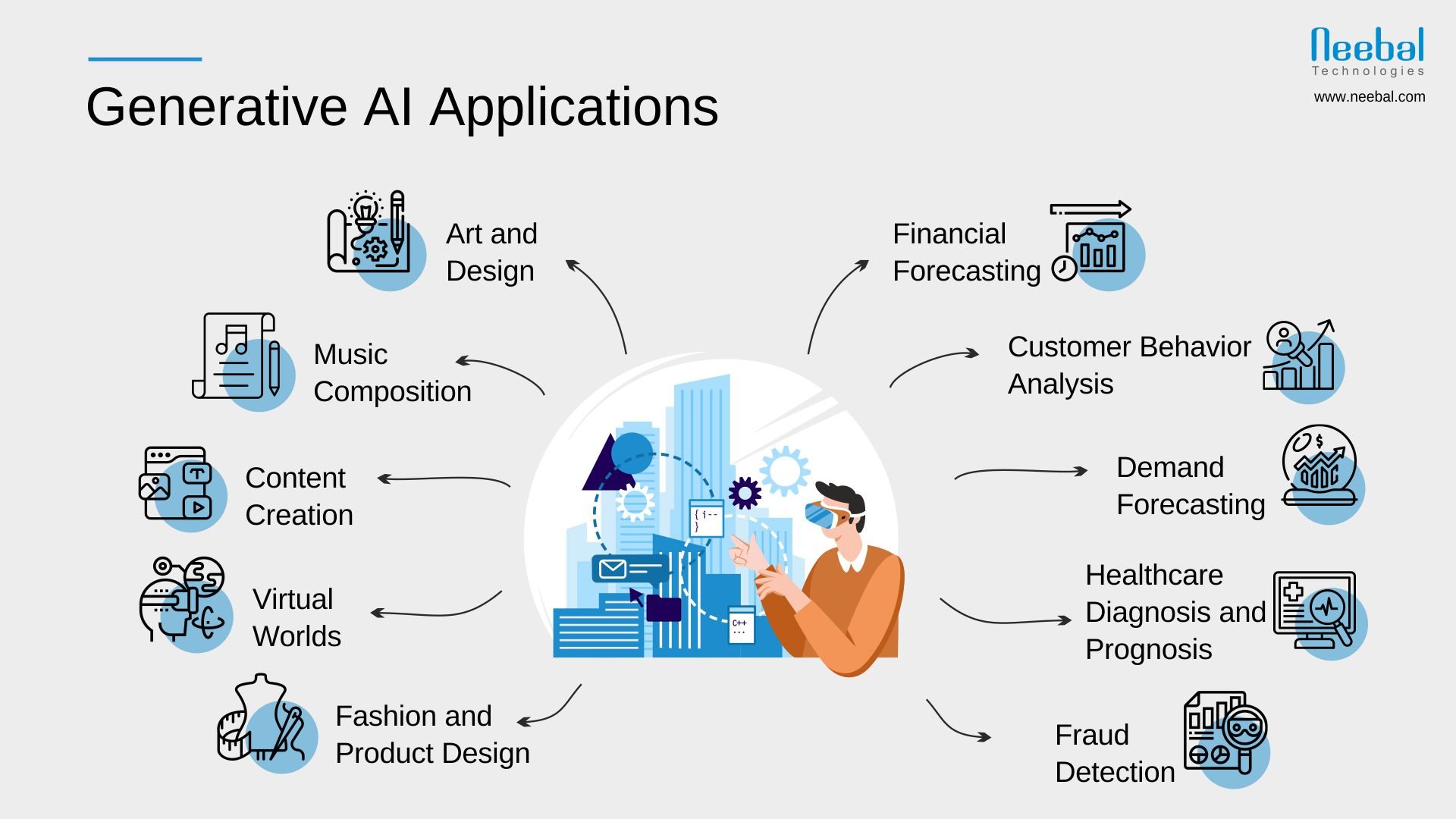

Generative AI (GenAI) can now be leveraged to tackle the data gap challenge. GenAI focuses on producing new, original content by learning from existing data. One of the major applications of GenAI has been to generate and improve algorithms. Many programmers are already using large language model (LLM) based AI assistance applications to generate simple algorithms and improve upon complex ones.

GenAI can help bridge the data gap in PdM

GenAI can help bridge the data gap in PdM

However, GenAI’s ability to successfully generate synthetic data or write ML algorithms is still to be tested in the industrial environment.

The Future of Predictive Maintenance

Despite the challenges, I believe that generative AI has the potential to democratize predictive maintenance. By addressing the data gap challenge, GenAI can help make PdM more accessible to manufacturers. As the technology advances, we can expect to see more widespread adoption of PdM.

The future of industrial AI is bright

The future of industrial AI is bright

In conclusion, generative AI can play a crucial role in closing the gap in predictive maintenance. As the technology continues to evolve, we can expect to see more innovative applications of GenAI in the industrial sector.